Mastering Material Management for Electrification Projects: A Comprehensive Guide

Electrification projects, such as the Last Mile initiative, are critical to expanding access to reliable energy for underserved populations. However, the success of such large-scale projects hinges on a fundamental yet often underestimated aspect: material management. Effective material management ensures that the right materials are available at the right time, in the right quantities, and at the right locations, minimizing project delays and cost overruns. This article explores the significance of material management in electrification projects and highlights how Emeran Systems’ ERP solutions can streamline this crucial process.

Why Material Management Matters

Material management involves the planning, sourcing, procurement, storage, and distribution of materials needed for a project. In electrification projects like Last Mile, where the aim is to connect remote or rural areas to electricity networks, the challenges of material management are compounded by factors such as logistical complexity, varying site conditions, and tight project timelines. Engineers and project managers must ensure efficient material flow to:

Avoid Delays: Timely availability of materials prevents work stoppages and ensures project milestones are met.

Control Costs: Effective inventory management reduces the risk of overstocking or understocking, optimizing procurement budgets.

Enhance Quality: Proper handling and storage of materials ensure they meet quality standards upon installation.

Improve Safety: Organizing materials on-site minimizes hazards and supports safe working conditions.

Achieve Sustainability: Efficient material use and waste reduction contribute to environmental and financial sustainability.

Reconcile Materials: Track allocated materials against those used to identify discrepancies and optimize usage.

Challenges in Material Management for Electrification Projects

Electrification projects often involve multiple sites spread across a vast geographical area, each with unique material requirements. Some key challenges include:

Complex Supply Chains: Coordinating with multiple suppliers for diverse materials like transformers, poles, cables, and fittings.

Remote Locations: Transporting materials to inaccessible or rugged terrains.

Inventory Tracking: Maintaining accurate records of materials at various stages of the project.

Real-Time Visibility: Ensuring stakeholders have up-to-date information on material availability and usage, including materials in-store, in transit, and already used.

Compliance and Documentation: Managing contracts, purchase orders, and quality certifications effectively.

Material Theft and Loss: Preventing unaccounted materials through robust security and tracking measures.

Overordering: Avoiding excess materials that may strain project finances, especially in contract-based projects where unused materials cannot be easily repurposed.

Financial Constraints: Balancing procurement costs with tight budgets to avoid delays and inefficiencies.

Emeran ERP System: A Comprehensive Solution

Emeran Systems’ ERP (Enterprise Resource Planning) platform offers a robust solution to these material management challenges. Tailored for engineering and construction projects, the Emeran ERP system integrates various functions to provide a unified approach to material management. Here are some key features and benefits:

1. Centralized Material Planning

The ERP system enables engineers to create detailed material requirement plans (MRPs) based on project schedules and design specifications. This reduces the risk of underestimating or overestimating material needs.

2. Real-Time Inventory Tracking

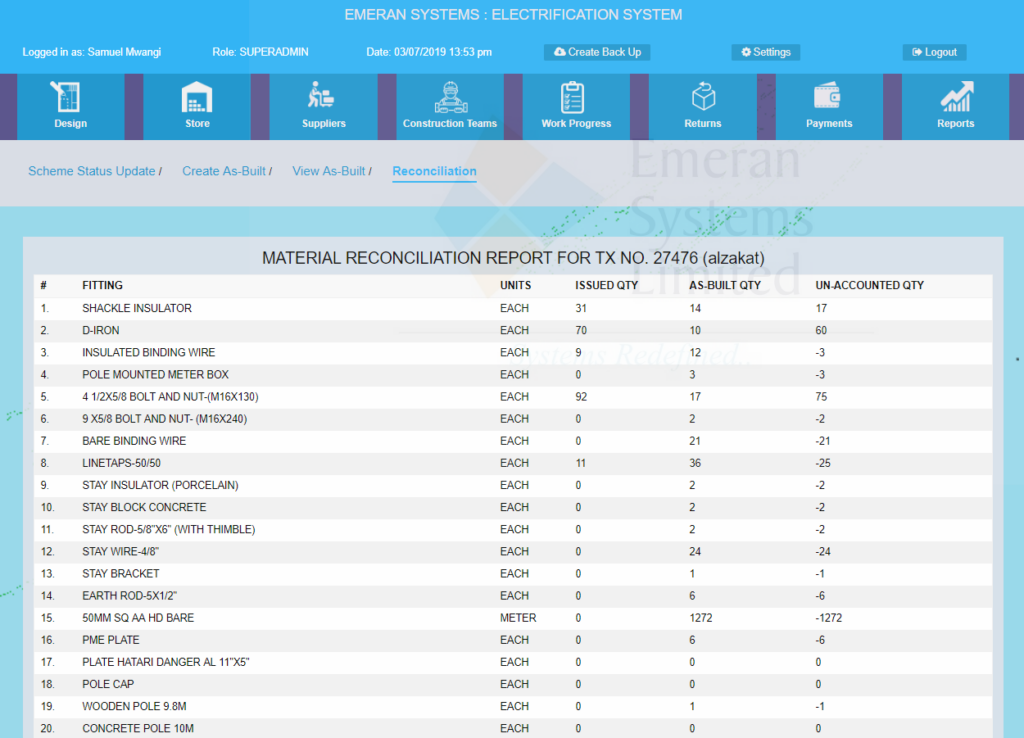

With Emeran ERP, you can monitor inventory levels across multiple warehouses and project sites in real time. This ensures accurate stock visibility, preventing delays caused by shortages. It also accounts for materials’ status—whether in-store, in transit, or already used—allowing for precise reconciliation.

3. Supplier and Procurement Management

The system streamlines supplier selection, purchase order generation, and vendor communications, ensuring timely delivery of high-quality materials.

4. Logistics Coordination

Emeran ERP facilitates transportation planning, route optimization, and delivery tracking, even to remote project locations. This reduces logistical inefficiencies and transportation costs.

5. Reporting and Analytics

The platform provides actionable insights through customizable dashboards and reports. Engineers can track material usage trends, project progress, and budget adherence to make informed decisions. Additionally, it compiles materials used for invoicing per project, simplifying financial management.

6. Compliance and Documentation

Emeran ERP ensures that all material-related documents, such as invoices, and delivery notes, are securely stored and easily accessible for audits and compliance.

Best Practices for Material Management in Electrification Projects

To maximize the benefits of an ERP system like Emeran’s, engineers should adopt the following practices:

Early Planning: Develop a detailed material procurement and logistics plan at the project’s inception.

Collaborate with Suppliers: Build strong relationships with reliable suppliers to ensure material quality and timely delivery.

Leverage Technology: Use the ERP system to automate routine tasks and improve accuracy.

Track Material Status: Regularly reconcile allocated materials against those used to avoid discrepancies and improve accountability.

Train Teams: Provide adequate training to project teams on using the ERP system effectively.

Monitor and Adjust: Continuously track material usage and adjust plans based on real-time data and project needs.

Conclusion

Effective material management is a cornerstone of success for electrification projects like Last Mile. It impacts not only the efficiency and cost-effectiveness of the project but also its long-term sustainability. By adopting modern tools such as Emeran Systems’ ERP platform, engineers and project managers can overcome logistical complexities and drive project success.

For more information on how Emeran Systems can transform material management in your electrification projects, visit emeransystems.com.